Orano USA partners with Tri Tool to develop a custom engineered solution to remotely sever underwater jet pump diffusers in Vermont Yankee nuclear reactor vessel

October 8, 2021

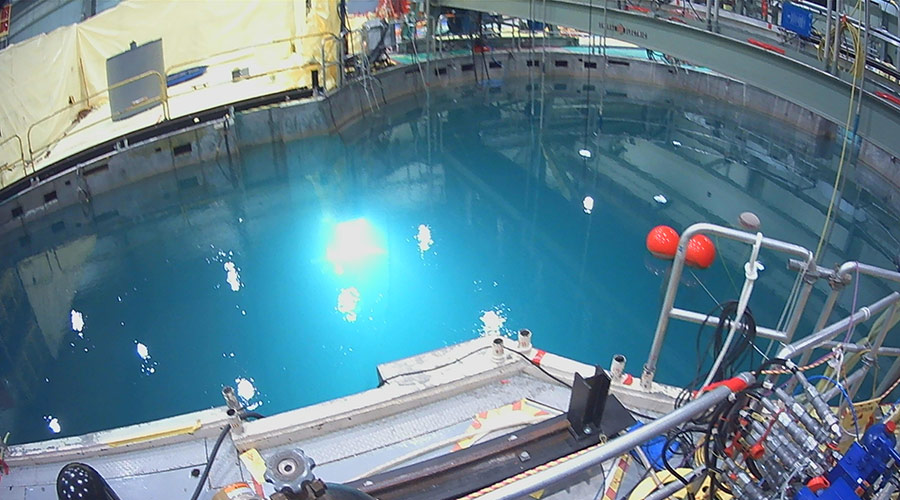

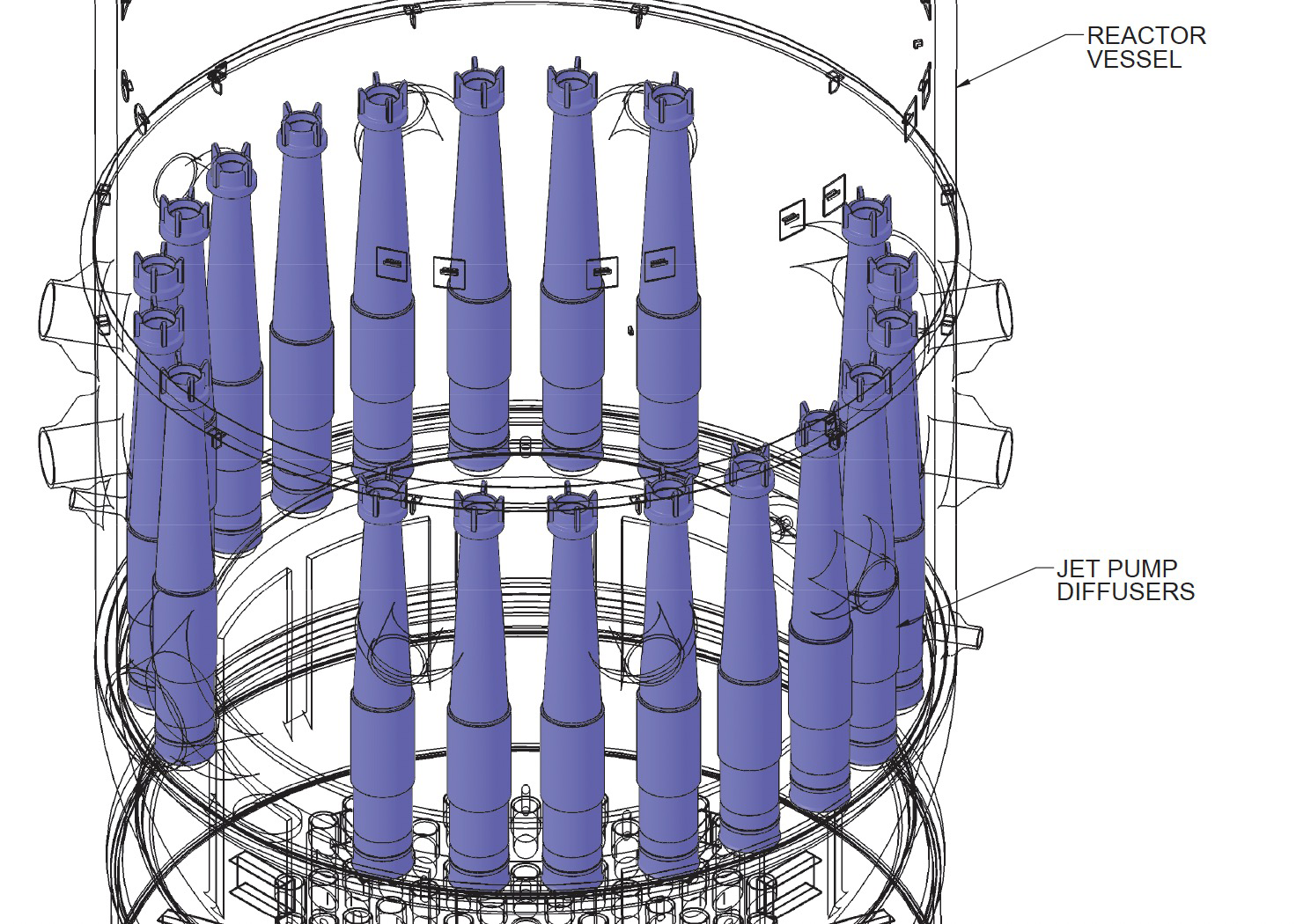

In 2014, the Vermont Yankee Nuclear Power Station permanently shut down. Orano USA, a leading technology and services provider for decommissioning nuclear energy facilities, was tasked in Phase 1 of the decommissioning project to depose a portion of the nuclear reactor pressure vessel and remove 20 underwater jet pump diffusers.

CHALLENGE

Tri Tool was tasked with assisting with the removal of 20 underwater jet pump diffusers contained in a highly contaminated environment. To safely sever the jet pump diffusers, Tri Tool had to develop a specialty tool that could be lowered down 70 feet underwater and remotely cut each diffuser in half mounted on the OD. Then, Tri Tool had to develop an additional ID mounted machine that could sever the other half of the pump.

SOLUTION

Tri Tool customized both systems on-site and in-situ to match the orientation of the jet pump diffusers. Using the 600 Series TRIMAX Machining System and the 600 Series SB Split-Frame Clamshell as the basis, Tri Tool developed two remote-controlled systems operated via cameras that lowered into the vessel and hydraulically clamped to each diffuser. Both systems were able to maintain the remnant.

VALUE

Originally given a timeline of two weeks to complete this project, Tri Tool finished ahead of schedule with zero incidents. The two systems that Tri Tool custom developed for this project worked so efficiently that they are being used by Orano USA to assist with the decommissioning of the Pilgrim Nuclear Power Plant in Plymouth, Massachusetts.

Learn more about Tri Tool’s solutions and services for power generation here.

About Tri Tool

Tri Tool is a global leader in the design and manufacture of custom MissionBuilt™ engineered solutions and high-performance PurposeBuilt™ precision machine tools for major industrial markets, including aerospace, government and defense, life sciences, power generation, oil and gas, and semiconductor. For over 49 years, we have partnered with the world’s top companies, providing state-of-the-art equipment, Field Services, and Rental Programs that increase productivity, optimize costs, and accelerate delivery. Unconventional innovation with extreme agility and proven results—that’s our thing, solving your toughest challenges, anywhere, in record time.

About Tri Tool

Tri Tool is a global leader in the design and manufacture of custom MissionBuilt™ engineered solutions and high-performance PurposeBuilt™ precision machine tools for major industrial markets, including aerospace, government and defense, life sciences, power generation, oil and gas, and semiconductor. For over 49 years, we have partnered with the world’s top companies, providing state-of-the-art equipment, Field Services, and Rental Programs that increase productivity, optimize costs, and accelerate delivery. Unconventional innovation with extreme agility and proven results—that’s our thing, solving your toughest challenges, anywhere, in record time.

What's your next mission?

Our staff and engineers are on the ready. Let Tri Tool get to work.