A Cut Above the Rest

When performing weld preps on pipe and tubing, you're only as good as your bits. That's why for over 50 years, Tri Tool has manufactured the finest consumables in the industry. To prove it, we put our Durabits up against lower priced competitors. The results? The competition couldn't cut it.

We put our Durabit1 to the test against 3 leading competitors to measure:

.jpg)

We put our Durabit1 to the test against 3 leading competitors to measure:

The Durabits Difference

Putting Durabits to the Test: A Benchmark Study

Through state-of-the-art design, unique manufacturing, and proprietary coating technology, Tri Tool's patented Durabits are "free cutting" (the edge stays under the chip) and extremely long lasting.

- Enables precise facing and squaring of high purity tube ends

- Coating provides durability and longer cutting-edge life over non-coated tool bits

- Compatible with 300 Series machines and 500 Series SQM modules

- Directs chips away from the ID of the tube

Putting Durabits to the Test: A Benchmark Study

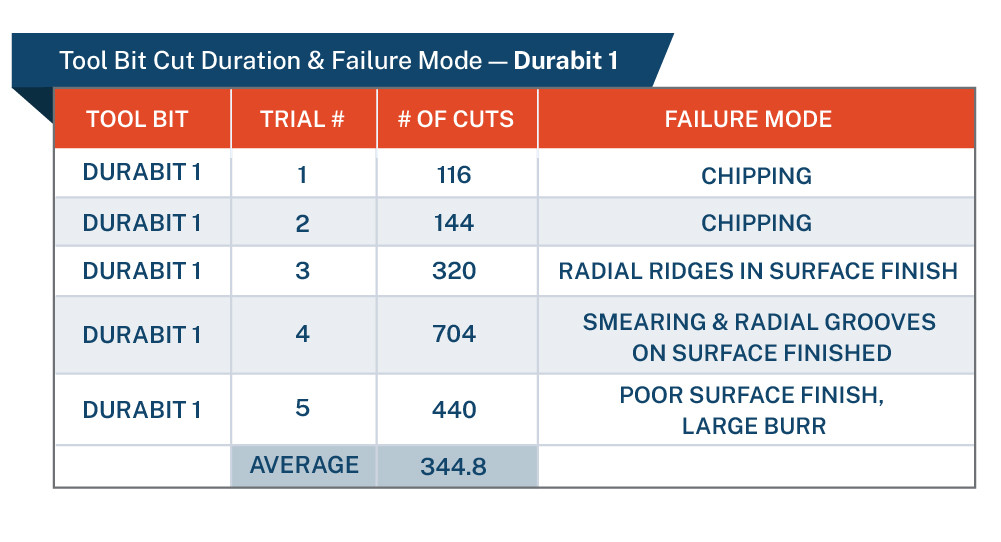

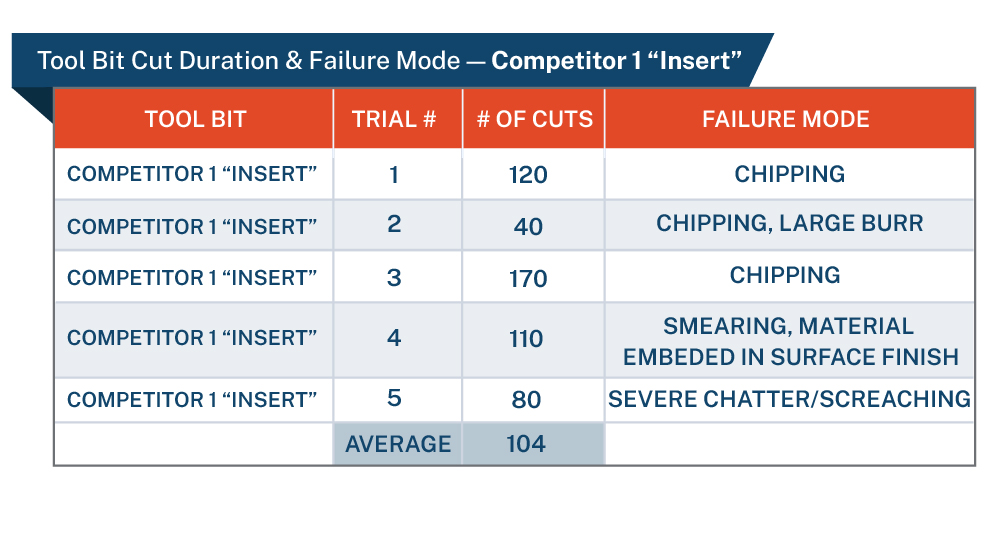

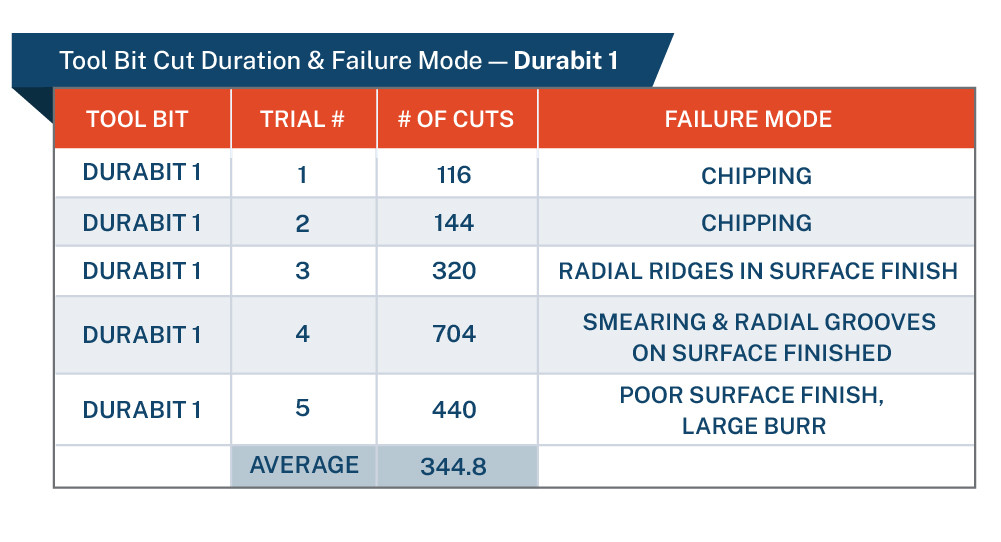

To test the performance and cost/value of our Durabit1 against three leading competitors, we conducted a benchmark study to evaluate three key value areas: cost, tool life and cut quality. Our results indicate Durabit1 lasts significantly longer, yields higher quality cuts, and costs significantly less per cut than the competition.

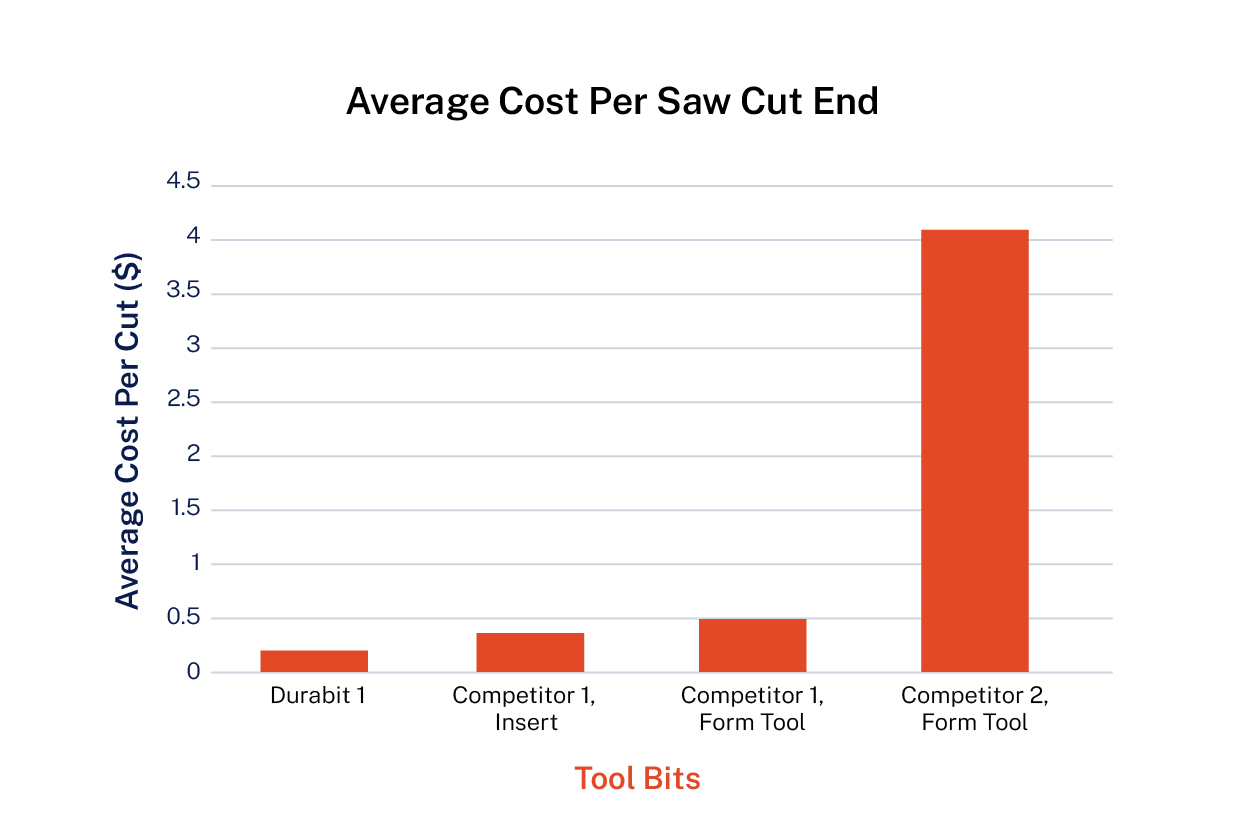

To evaluate cost effectiveness, we compared the average cost per cut between Durabit1 and the three leading competitors. Results indicate Durabit1 is significantly more cost effective.

Durabit1 costs:- 2x less than Competitor 1, Insert

- 3.3x less than Competitor 1, Form Tool Bit

- 25x less than Competitor 2, Form Tool Bit

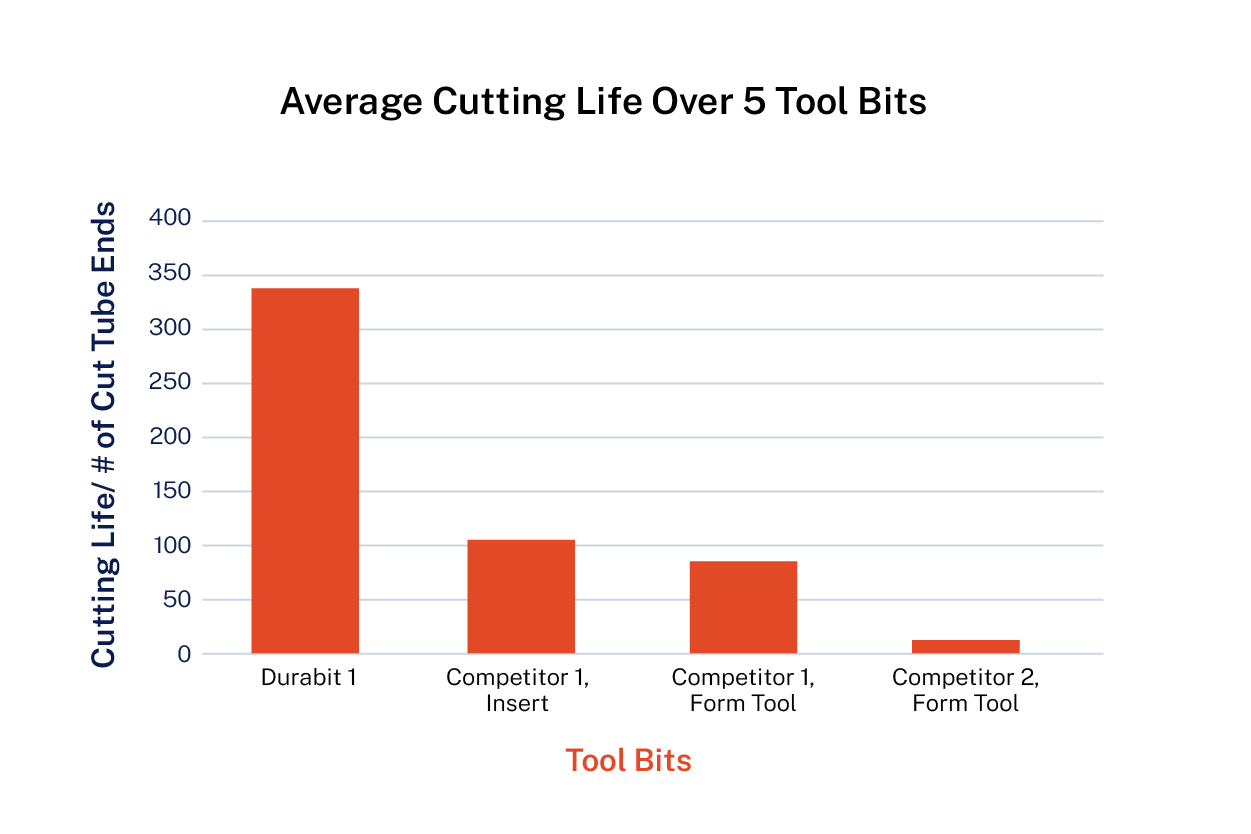

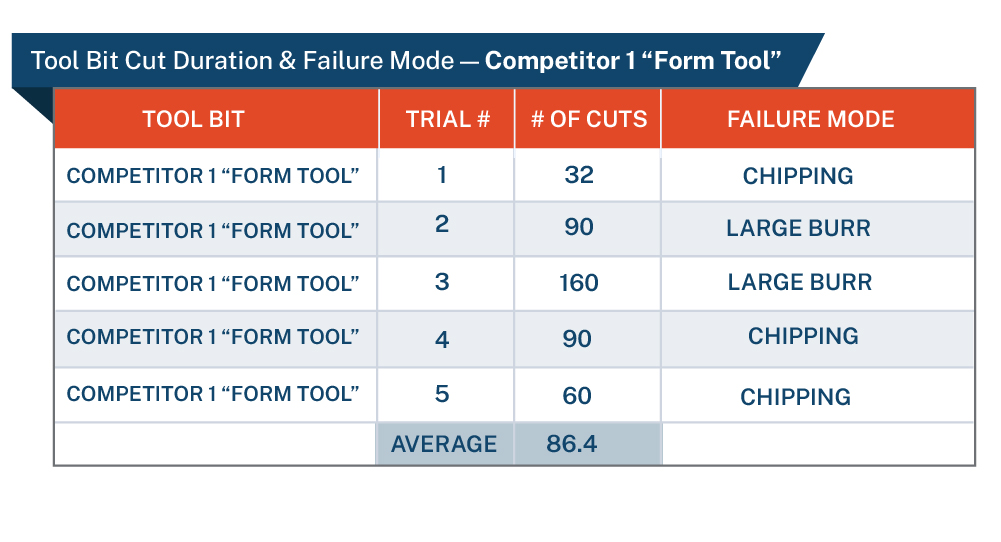

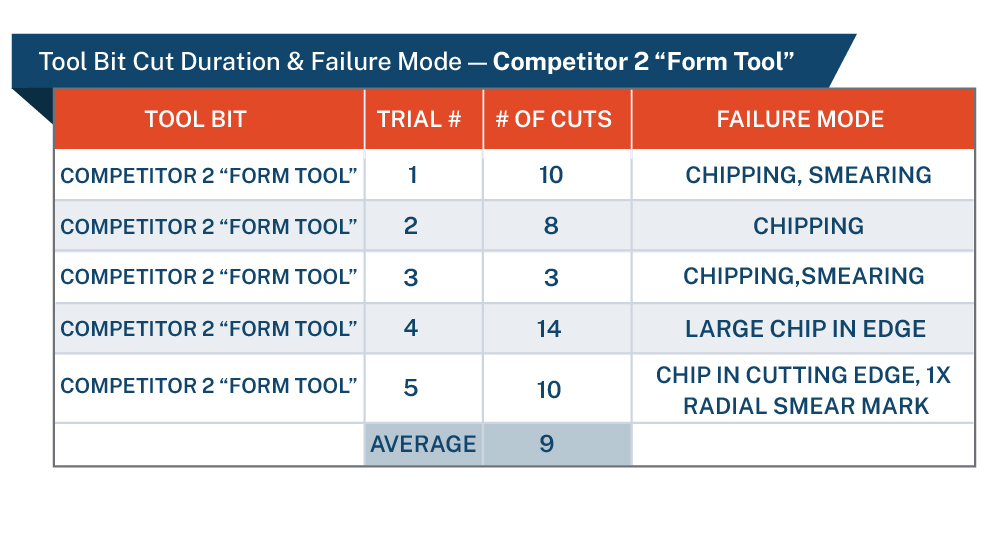

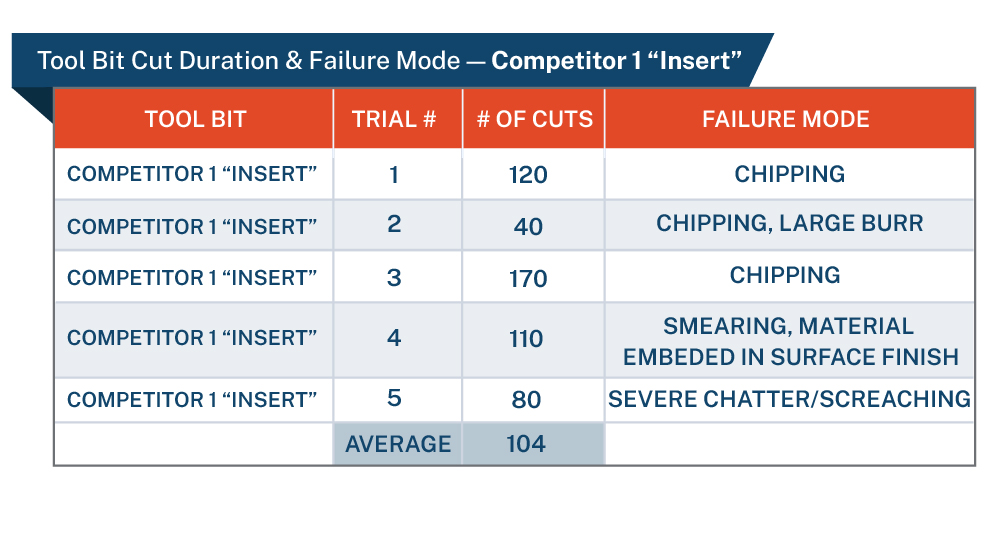

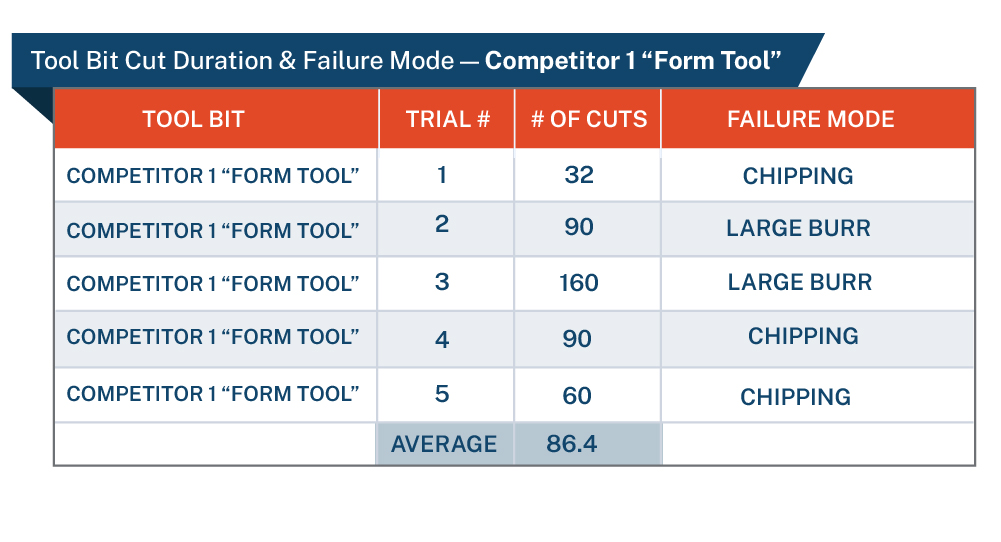

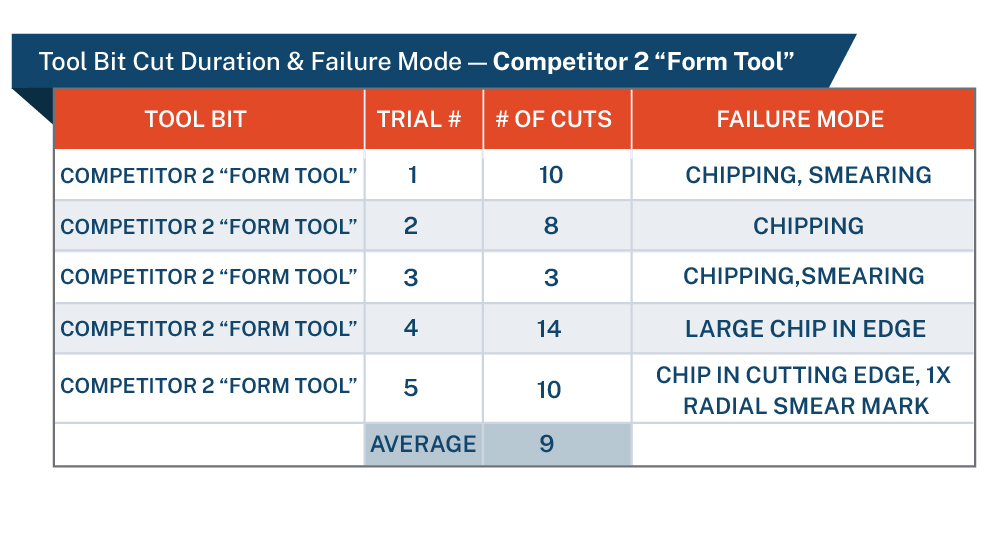

To evaluate tool durability, we tested the average cutting life of each product over 5 tool bits. Results indicate that Durabit1 lasts more than 3x longer than the closest competitor, which is a two-sided insert that theoretically should provide double the cuts.

Durabit1 lasts:- 3.3x longer than Competitor 1, Insert

- 4x longer than Competitor 1, Form Tool Bit

- 38x longer than Competitor 2, Form Tool Bit

To evaluate cut quality, we tested the surface finish and burr of each product. Durabit1 produced consistent, manageable chips with no signs of heat discoloration. In comparison, the Competitor 1 Form Tool Bit appears to be constructed of an inferior material or excessively hardened, resulting in premature chipping of the cutting edge. Similarly, the Competitor 2 Insert yielded severe chatter marks and screeching, which may be the result of little-to-no helix angle in the tool bit.

|

|

|

|

|

|

|

|

Customer Testimonials

I have been using/sending out the Durabit 1 to jobsites and crews since I have been working for Harder Mechanical. These are the longest lasting and most durable ones I have seen. I tried other ones and they don't compare. We will continue to use these as long as they will make them.

Andy Pichler

Harder Mechanical

Thank you Tri Tool for making superior products. It is always easy to get in touch with Tri Tool for technical issues. I will only buy Durabits from now on. The longevity and high quality, making perfect preps for orbital welding and the dura bit will outlast any other knock off brands on the market.

Gary Lillard

Dynamic Systems, Inc.

We have recently tried some other facing and cutting bits that have come on to the market. We have put them through their paces in our busiest areas. Our findings were that they do not stand up to the durability and strength of the Durabit Blades. Our crews have asked to only use the Durabit. The strength and quality of the Durabit we get from Tri Tool seems to stand up to many more cuts than any other facing/cutting bits we have tried.

Derrick Davis

J.B. Henderson Construction Co.

Have questions? Hit us with your best shot.

Let's start a conversation.

The non-blind benchmark test conducted between Tri Tool Durabits tool bits and three leading competitors' consumables tool bits involved rigorous testing by our engineering team over a 30-day testing period. The study encompassed testing five tool bits for each brand, using the same machine and maintaining equal and consistent tooling, tubing, materials and application methods throughout all tests. However, it is important to note that benchmark tests, while designed to provide reliable data, may still be subject to inherent limitations. Results may vary based on specific operating conditions and individual usage patterns. This notice serves to emphasize that the findings presented should be considered as a reference point rather than an absolute measure of performance for all scenarios.

.png)