Cold Cutting Pipe and Tube: A Precise and Efficient Solution for Industrial Applications

The strategic deployment of pipes and tubes stands as a common thread weaving through the intricate tapestry of both the aerospace and semiconductor industries. These vital channels play pivotal roles in ensuring structural integrity, fluidic precision, and thermal management, which are the essence of advanced engineering solutions essential for the functionality and performance of intricate systems.

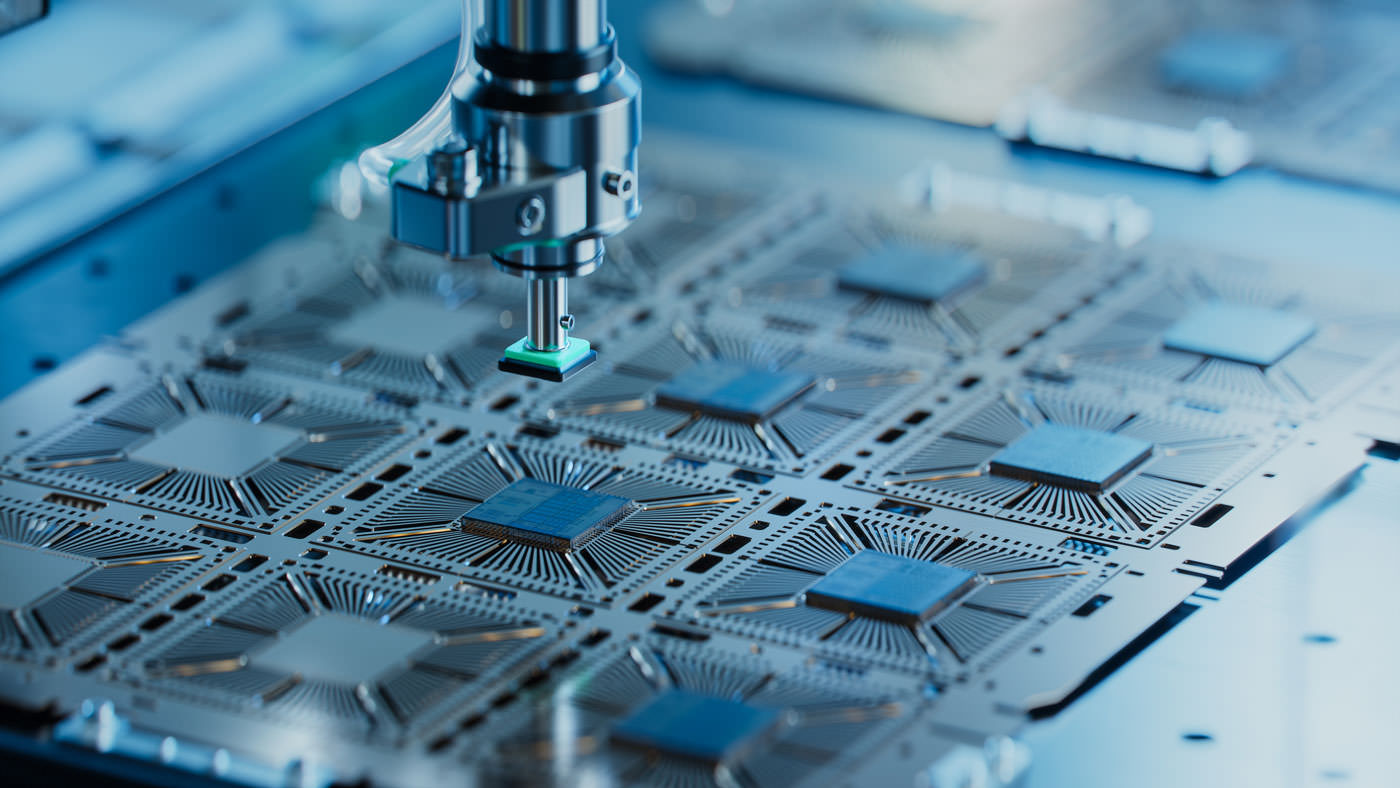

The aerospace and semiconductor industries intertwine precision engineering and cutting-edge technologies, where pipes, tubes, and the transformative technique of cold cutting play important roles. In aerospace, these channels are integral to ensuring the structural integrity and fluidic efficiency of airframes and propulsion systems. Simultaneously, in the semiconductor realm, they guide the intricate processes within microscopic spaces.

Cold cutting, a technological cornerstone in both industries, minimizes thermal impact and optimizes material removal, contributing to the fabrication of components in aerospace and refining semiconductor devices with precision.

Cold Cutting 101:

Cold Cutting: A method of cutting pipes and tubes without the application of heat.

Unlike traditional methods, such as torch cutting or grinding, cold cutting methods utilize mechanical, hydraulic, or pneumatic tools to sever pipes and tubes cleanly.

Methods of Cold Cutting

Cold Cutting’s versatility and range of applications make it an indispensable process for professionals in various fields. By choosing this method, industries can ensure the structural integrity of their systems while minimizing safety hazards associated with traditional hot cutting techniques.

Band Saws: Commonly used for cutting pipes and tubes consisting of a continuous band of toothed metal that rotates around two or more wheels, cutting through the material with precision. They offer high accuracy and are suitable for both straight and angled cuts.

Circular Saws: Equipped with specialized blades, which are effective for cold cutting. These saws provide a quick and clean cut, making them suitable for a variety of pipe and tube materials.

Rotary Pipe Cutters: These handheld or automated cutters use a rotating blade to achieve precise cuts. Particularly useful for cutting pipes and tubes with thicker walls or in confined spaces.

Water Jet Cutting: Uses a high-pressure stream of water mixed with abrasive particles to cut through pipes and tubes. Suitable for a wide range of materials, including metals and plastics.

Benefits of Cold Cutting

As technology continues to advance, cold cutting methods are likely to become even more refined and applicable in an increasing number of industrial settings.

Safety: Cold cutting eliminates the risks associated with heat-based methods, such as fire hazards, toxic fumes, and heat-affected zones. It ensures the safety of operators and the surrounding environment.

Precision: Cold cutting methods provide accurate and clean cuts, minimizing the need for additional finishing work. This precision is crucial in industries where tight tolerances are required.

Minimal Material Distortion:: Unlike heat-based cutting methods, cold cutting minimizes material distortion, ensuring that the structural integrity of the pipes and tubes is preserved.

Versatility: Cold cutting methods can be applied to a wide range of materials, including metals, plastics, and composites, making them suitable for diverse industrial applications.

Negatives of Cold Cutting

It's wise to acknowledge that while cold cutting methods offer significant advantages, there are also considerations regarding their implementation. Understanding the potential drawbacks is crucial for a comprehensive evaluation. Balancing the positive and negative aspects allows for a dual perspective, enabling industries to make informed decisions about integrating this technique into their manufacturing processes.

Tool Wear: Cold cutting methods, especially those involving high-speed tools, can lead to increased tool wear. This results in more frequent tool replacements and maintenance, adding to operational costs.

Equipment Costs: The initial investment in specialized equipment can be substantial. This can act as a financial barrier for smaller operations or businesses with limited budgets.

Energy Consumption: Depending on the method, some cold cutting processes may demand significant energy consumption, contributing to operational costs and potentially impacting the overall environmental footprint.

Process Speed: In certain applications, cold cutting methods may have slower processing speeds compared to traditional hot cutting methods. This could be a limitation in industries where high output is critical.

Surface Finish: Achieving a smooth surface finish can be challenging with certain cold cutting techniques, potentially requiring additional steps for post-processing and finishing.

Applications

These real-world applications highlight how cold cutting has become a go-to solution, not just for its theoretical advantages, but for its tangible impact in addressing the specific needs of diverse manufacturing sectors.

Pipeline Maintenance and Repair: Cold cutting is widely used in the oil and gas industry to replace or modify sections of pipelines without disrupting the flow of materials.

Manufacturing: Manufacturers use cold cutting methods to shape pipes and tubes for various industrial equipment and machinery.

Shipbuilding: The shipbuilding industry relies on cold cutting for precision cuts in pipes and tubes used in vessel construction.

Nuclear and Power Plants: Cold cutting is crucial for maintaining and repairing systems in nuclear and power plants, where safety and precision are paramount.

Aerospace: Utilizing techniques such as abrasive water jet machining or laser cutting, provides a distinct advantage by avoiding thermal distortions in high-strength alloys and composites. This process is crucial in the fabrication of components like turbine blades and structural elements, where minimizing heat-affected zones is essential for maintaining material properties and structural integrity.

Semiconductor: Cold cutting is critical in the precision machining of silicon wafers and other semiconductor materials. It minimizes heat transfer to the delicate semiconductor materials, preventing thermal stress and ensuring the integrity of intricate microstructures.

As we navigate the intricate balance between the benefits and considerations of cold cutting, it becomes evident that its adoption is not merely a technological trend but a strategic response to the evolving demands of precision engineering. The seamless integration of cold cutting techniques underscores a shift in manufacturing practices, where efficiency, sustainability, and product quality converge. In an era defined by rapid technological advancement, cold cutting emerges not just as a method but as a key enabler, propelling industries toward new frontiers of innovation and excellence.

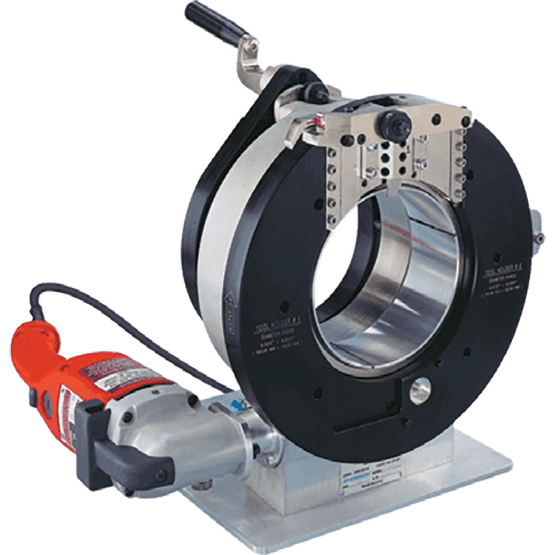

At Tri Tool Technologies, our commitment to utilizing cold cutting techniques in various industries is exemplified through our cutting-edge product offerings. Among our impressive lineup are the 572AC and 576AC, which exemplify their commitment to precision and efficiency. The 572AC, renowned for its exceptional accuracy, is the go-to choice for intricate cutting tasks. It ensures that semiconductor components maintain the highest quality standards. The 576AC, on the other hand, is the epitome of reliability, capable of handling even the most demanding applications while delivering consistent, burr-free results.

The 572AC represents the pinnacle of precision cold cutting. This versatile tool is designed with a focus on stability and accuracy. Its stainless-steel frame ensures robustness, while the advanced servo motor drive system allows for a cutting accuracy within microns. This level of precision is essential in semiconductor manufacturing, where the smallest deviations can lead to product failure or reduced performance. The 572AC's control system offers real-time monitoring of cutting parameters, providing unprecedented control over the cutting process.

On the other hand, the 576AC is a testament to Tri Tool's dedication to reliability. It is engineered to meet the most demanding applications in the semiconductor industry, ensuring consistent and burr-free results. The advanced linear rail system guarantees smooth and precise motion, while the highly accurate laser displacement sensor measures tube or pipe OD with precision, ensuring that every cut is precisely on target. The 576AC's control system allows for the creation of intricate cutting patterns, offering unmatched flexibility in semiconductor manufacturing.

In an industry where precision and accuracy are paramount, Tri Tool Technologies remains at the forefront, offering a range of tools that cater to various industries unique technical demands. We prioritize safety, environmental responsibility, and cost-effectiveness in all our services. Clients who choose our solutions can trust that they are investing in results that enhance operational efficiency while adhering to the highest safety standards. By continually pushing the boundaries of what cold cutting can achieve, we are proud to contribute to the success and progress of industries that rely on precision, safety, and efficiency.

Need support with repairing your piping system or want to chat about our machining tools or services?

Tri Tool's Field Services can help.

We understand that each project and requirement is unique, and we are here to provide the answers to your questions and meet your specific needs. Whether you're seeking expert advice on the best cold cutting solutions for your project or looking to explore our extensive tool catalog, we invite you to get in touch with our dedicated team. We are readily available to address your inquiries, offer guidance, and assist you in finding the ideal solutions for your pipe and tube cutting challenges. Don't hesitate to reach out to us today - your success is our priority.

Contact Tri Tool Field Services

For those seeking to elevate their industrial operations with our cutting edge equipment, the experts at Tri Tool Technologies are ready to partner with you. Contact us today or call (888) 305-1337 to explore how our products can ensure leak-free, efficient, and safe operations, while reducing downtime and saving serious costs.

What's your next mission?

Our staff and engineers are on the ready. Let Tri Tool get to work.